Tools, tools, tools.

Remember those tools I was talking about? Well one of the tools I need to de-burr/smooth the edges of the large aluminum skins is a "double edge de-burring tool".

I ordered it online sunday evening so it should have shipped Monday. I was expecting to receive it on Wed after work, but no luck. Now it is Thursday evening and I have hit a stalling point.

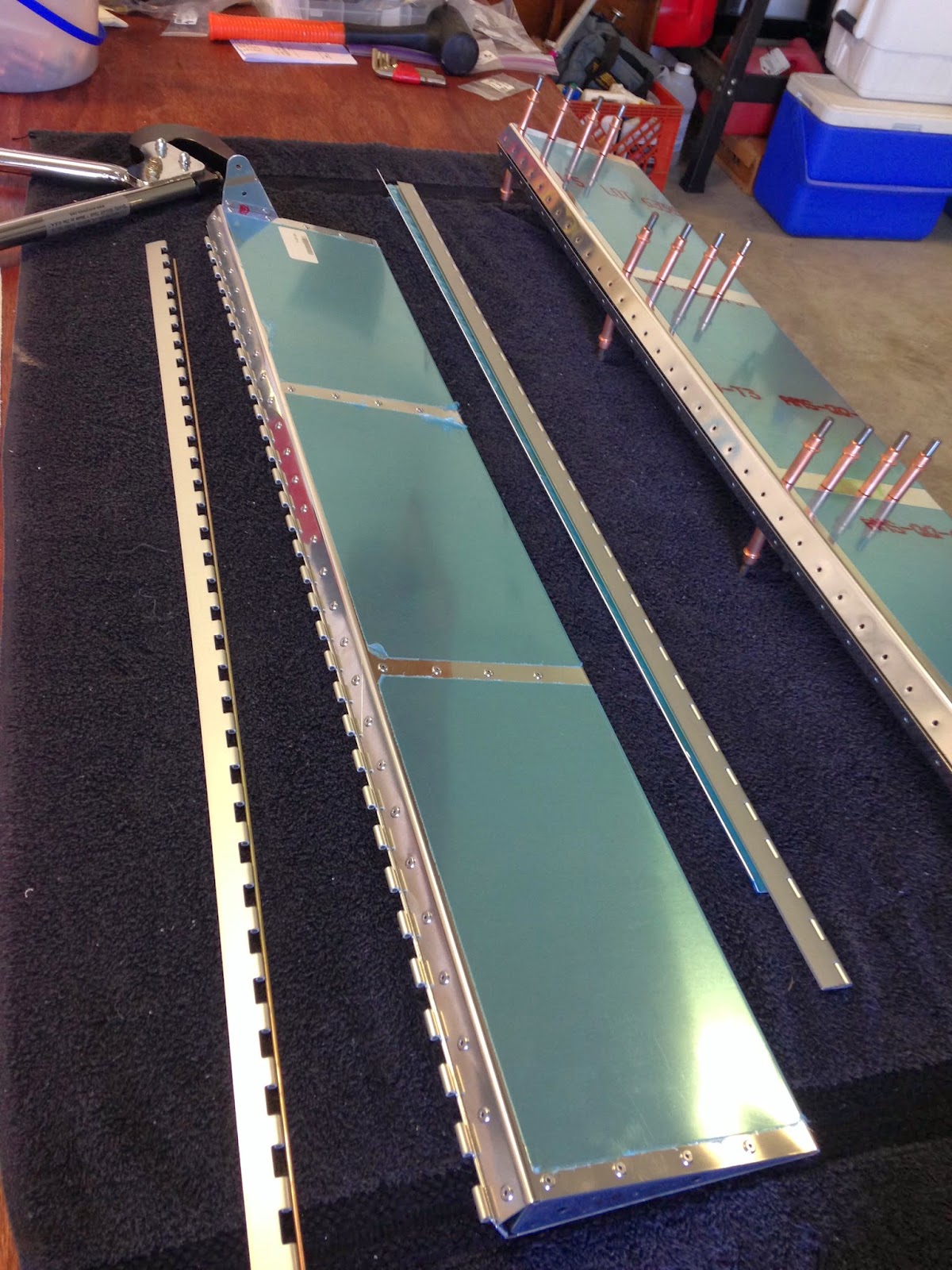

The VS is all ready to button up with about 150 blind pulled rivets each side. Problem is that I need to de-burr the edges of the skin before riveting it together. Here are a few pics of the skeleton going into the skin and the assembly cleco'd together (a cleco is a temporary spring loaded fastener). This is as far as I can go on the VS assembly until the tool arrives.

On to the Rudder.

Without being able to go any further on the VS, I decided to move onto the Rudder. The rudder is the aft extension of the VS that pivots left and right from the rear spar of the VS. This is linked to footpedals in the cockpit and controls the airplane's horizontal L/R movement. Anyway....

The rudder assembly goes together much like the VS assembly. The main spar is matched up with some spar caps. These are smaller pieces that nest into the main spar to provide additional support for areas where hinges mount or areas that will carry a higher stress load. They can be seen in this photo along with a hinge (temporarily mounted with clecos).

Additionally, the rudder spar has a control horn attached to the bottom of it. This is where the control linkages will eventually connect the rudder to the cockpit control pedals.

From this point, the rudder ribs will attach, perpendicular to the rudder spar, to create the skeleton of the rudder. The skeleton will then be slipped inside the rudder skin and riveted together; similar to the VS assembly.

Seems simple and straight forward. The devil is in the details, or should I say de-burring. Every hole has to be final drilled, then de-burred. Every spar and rib has to have all edges smoothed and de-burred. This is because fine cracks along the edges can turn into small cracks over time, which can turn into large cracks. You can get the point from here.

Truth is, this aircraft will not be aerobatic and will be flown more like a sport sedan than a race car. The stress loads I will eventually place on the aircraft will likely never give it an opportunity to present a problem. However, I am one of those people that believe in planning for the worst case scenario and enjoying when it doesn't happen.

Another road block.

The next step calls for the rudder spar to be test fit to the pivot hinges on the rear spar of the completed VS assembly. Well, no completed VS assembly, so no way to do this. I can't move forward with the rudder until it passes the test fit. Once the spar caps and hinges are riveted into place, it would be a royal pain to have to change/adjust it.

I could move onto the next assembly or start cleaning up all of the rudder ribs in preparation for later steps that involve them, but the anal retentive side of me is starting to get sketchy about moving too far past multiple uncompleted steps.

Carice's Aunt, Uncle and Cousins are coming into town for the weekend tomorrow. There has been talk about taking the boat out on the river, so I will be taking a few days off building. Hope everyone has a good "Hallmark Holiday" aka Valentine's Day.